Categories

How to Install WPC Decking: Expert Tips and Tricks

Understanding WPC Decking

What is Wood Plastic Composite (WPC)?

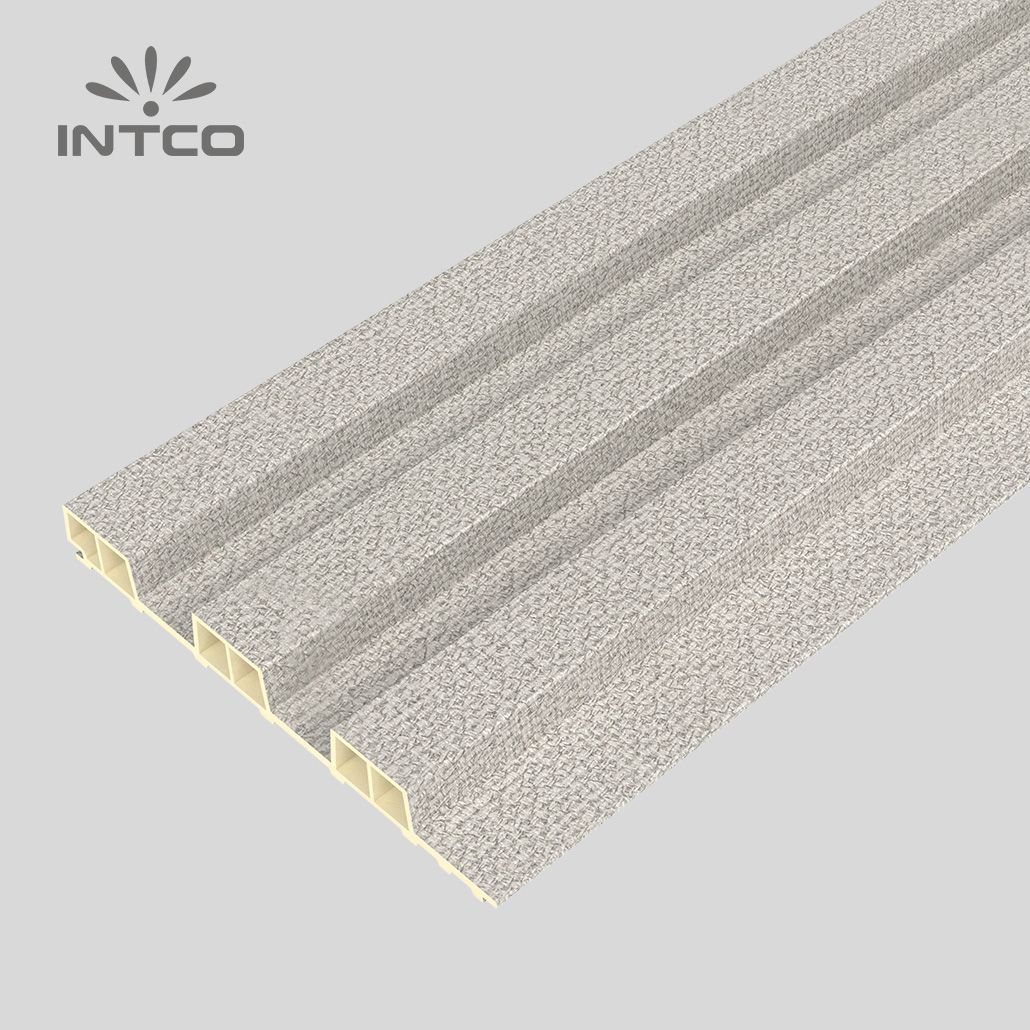

Wood Plastic Composite(WPC) is a revolutionary type of plastic material that could be used instead of wood in a great number of fields. This material combines beautiful wood aesthetics with the durability of plastic and low cost. WPC is produced by mixing recycled wood fibers and thermoplastics. The resulting material is both beautiful and tough. Owing to the advantages over traditional wood offered by the type of plastic it is made from, the material is quickly becoming very popular among both homeowners and contractors involved in construction and landscaping.

Advantages of WPC Decking

Durability and Longevity

The application area of WPC lumbers is facilitated by the engineering of their durable substance. It is tailored so as to withstand moisture or being subject to UV radiation, while thermal fluctuations do not have any effect on WPC decking or WPC wall panel. Unlike regular wood, it does not warp, decay, or splinter, thus allowing for opportunities of refined design on patios, balconies, and other surrounding areas. It is evident that the longevity of the product ensures that the investment pays off, which, consequently, minimizes the potential needs for replacements or repairs.

Low Maintenance Requirements

Among the most significant advantages of WPC decking is that it is not high-maintenance. Often, it does not require staining, sealing, or painting on a regular basis to preserve its look. Soap and water are typically enough to keep a population looking great and fresh. Thus, homeowners do not waste much time to tend to the installation and save some additional funds that may be required for its maintenance over the years. Moreover, they do not need to worry as much about the constant decay of the material.

Resistant to Weather Elements

INTCO Decor outdoor products can handle any climatic conditions as it can be both rain and snow and exposed to the Sun without suffering with the material itself deteriorating. This makes the colors and types of surfaces of the properties not to disappear or become flat quickly. As a result, the owners of the properties can be sure to enjoy the outdoors irrespective of the season.

Preparation Before Installation

Cleaning the Deck Area

In the process, users should ensure every part of the deck is cleared including hidden sections between the boards to eliminate even the smallest dirt particles. This step helps prevent damage to the WPC and its supports caused by trapped dirt leading to unevenness or permanent stains and spots. The uniform groundwork will facilitate the users to install the WPC on a leveled ground as they had intended for a better final look.

Checking for Surface Levelness and Stability

After cleaning, the next perspective is to assess the levelness and stability of the surface. Use a level tool to determine any dips or rises within the area. It is crucial to make any adjustments before installing the WPC decks because once the decks are been installed in a surface that is not stable, it becomes difficult. Additionally, in the case of incorrect leveling option, it could result in complexities like formation of pools of water on the surface and very high chances of the decks moving over time. Adjusting the level of your surface, you will have made the decks stable and visually attractive.

Essential Tools Required

Having the right tools is crucial to installing WPC decking properly. Typically, you will require a circular saw, a drill, and a level to cut panels, fix screws, and keep surfaces flat. A push block should help you handle the saw more effectively. Other essential tools are a measuring tape to keep track of the required sizes, a pair of safety goggles, and a pair of gloves. Overall, if you want to complete your project successfully, you need to prepare yourself properly and provide all required tools to ensure quick and accurate installation.

Laying the Foundation for WPC Decking

Building a Sturdy Frame Construction

The major factor of any WPC decking project is the solid frame. The majority of all support structures are made of treated lumber or additional composite material. However, regardless of the materials used, the foundation has to be square and properly anchored. This approach could be explained not only by the fluctuations in weather but also by an overall temper of the structures’ treatment. A substantial frame is required for ensuring the longevity of the WPC decking; thus, this is the most crucial part.

Positioning Joists Correctly

After assembling the frame, the next step is to locate the joists properly. They must be placed close to one another and secured with screws in order to create a solid foundation. Depending on what the decking boards are made of, a space of 16 to 24 inches is typically required; however, the best recommendation can be found in the manufacturer’s directions. Not only do properly located joists enhance the deck’s strength, but they also enhance its looks by ensuring the decking aligns with the surface consistently.

Installing the WPC Boards

Using Starter Clips

The initial step in the installation of WPC decking is with the use of starter clips. These clips are essential in holding the first row of boards tightly in place, ensuring that the edges are stable and not moving. The clips are also usually attached to the joists or beams of the deck, allowing the deck boards to slide perfectly into place. It is important to note that the clips have to be screwed at equal spacing and tightly for the overall stability of the deck and enhance a neat appearance in the process.

Securing the Boards

After the starter clips are in the right place, the next step is to secure the WPC boards. Each board should be fastened under the clips per the manufacturer’s recommendations, which are usually with any kind of hidden fastener to avoid any screw being seen. Start by placing the first board against the starter clips, ensuring the edges have the right alignment, and then secure the board properly onto the joists. Regardless of the fact that the entire structure will be very durable even in the case of highly humid and wet environments, it is advisable to use stainless steel or coated screws which will not be subject to rust and corrosion. This assembly step is followed to ensure stability and avoid loose WPC boards that could potentially be dangerous.

Proper Alignment and Spacing

The proper alignment and spacing of WPC boards is essential both for their functionality and good looks. The boards should be laid down with equal gaps between them if to allow for drainage and space for expansion due to temperature fluctuations. The gap between boards should be between 1/8 and 1/4 inch but the exact width depends on the material used. Use spacers or a pice of equipment for maintaining equal gaps between boards. This will help make the result look professional and polished, and also will help avoid the accumulation of moisture in the gaps between boards, which may cause other maintenance problems in the future.

Finally, if you have any questions, whether it’s installation or product selection, you can contact INTCO Decor, a professional building materials manufacturer. We have rich installation solutions and material technology knowledge, and we can also design customized installation plans for you to further enhance your installation experience.